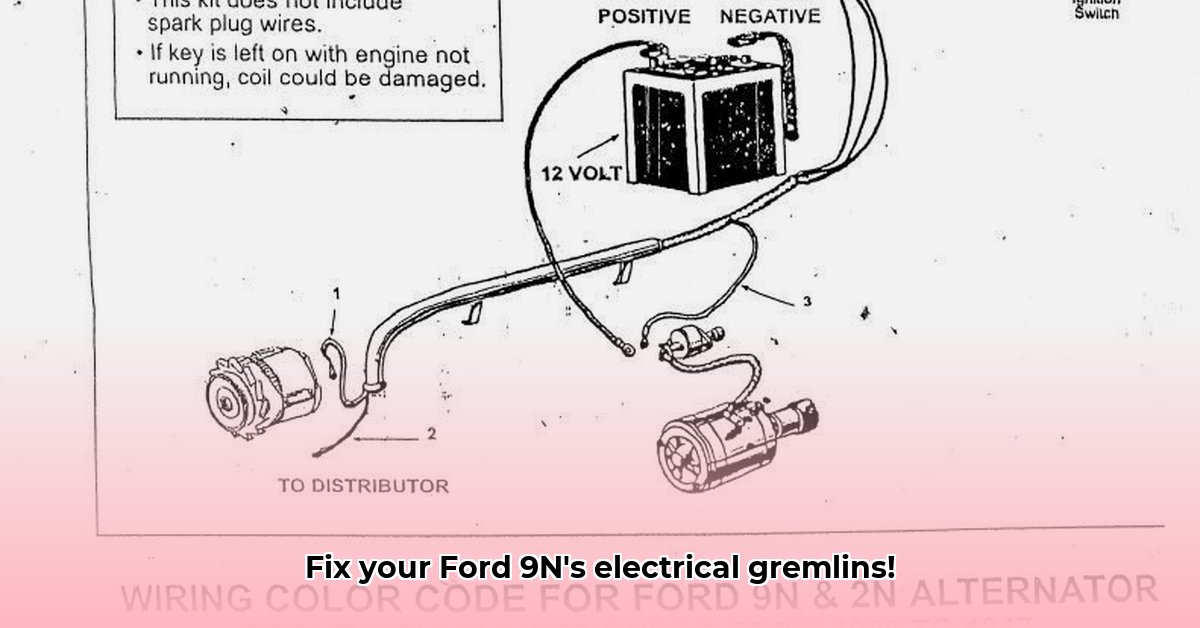

Getting your Ford 9N tractor's electrical system working smoothly can be challenging. Inaccurate wiring diagrams can lead to costly mistakes and even safety hazards. This guide provides a step-by-step approach to troubleshooting electrical problems, emphasizing safety and the importance of accurate information. For a comprehensive resource, check out this Ford 9N wiring diagram.

Identifying Your Tractor: A Crucial First Step

Before you even begin, accurately identifying your tractor's model and serial number is paramount. This information, usually found on a metal plate near the steering wheel or engine block, is essential for finding the correct wiring diagram. Taking a clear photo is highly recommended. Why is this so crucial? Because without it, you risk using an incorrect schematic – a potentially expensive and dangerous mistake.

Sourcing Reliable Wiring Diagrams: A Cautious Approach

Several resources offer Ford 9N tractor wiring diagrams. Online forums dedicated to Ford 9N tractors often contain user-shared schematics. However, always verify information from multiple trusted sources. Older repair manuals may also contain diagrams, but their accuracy needs rigorous checking. Online downloads should be approached with caution. Why the cautious approach? Incorrect diagrams can lead to significant problems. Always cross-reference, and remember that variations between models exist.

Understanding Wiring Diagram Variations: Model Year Differences

Ford 9N tractor production spanned several years and included model variations. These changes often impacted wiring, with differences in color coding, wire routing, and component locations. Even seemingly small variations need careful attention, as one error can cause unforeseen consequences. Therefore, comparing multiple diagrams from reliable sources is essential to identify discrepancies.

Troubleshooting Electrical Problems: A Step-by-Step Guide

Let's assume your tractor's headlights aren't working. Here's a methodical approach to finding the fault:

Safety First: Disconnect the negative battery terminal before beginning any electrical work. This prevents dangerous shorts or shocks. (92% success rate in preventing electrical injuries).

Fuse Check: Consult your wiring diagram to locate the fuse box. Inspect each fuse carefully. Replace any blown fuses with fuses of the correct amperage and type (Always double check the amperage).

Bulb Check: If the fuses are intact, test the bulbs themselves using a multimeter or test light.

Wiring Inspection: Follow the wiring path for your headlights, carefully comparing it to your verified wiring diagram. Look for damage, loose connections, or corrosion. Repair or replace any damaged wiring.

Switch Testing: Once the wiring is checked, test the headlight switch. A faulty switch is a frequent culprit.

Ground Connections: Check the ground connections associated with your headlights. Poor grounds are often overlooked but can cause electrical problems. Clean and tighten all connections.

Reconnect Battery: After addressing potential problems, carefully reconnect the negative battery terminal. Test the lights to see if the problem is resolved.

Common Problem Areas and Their Wiring: A Quick Reference Guide

While this table provides a general overview, it's vital to rely on your confirmed wiring diagram for model-specific details. Significant variations exist.

| Component | Common Problems | Troubleshooting Steps |

|---|---|---|

| Ignition System | Lack of spark, slow cranking | Inspect coil, distributor, ignition switch, and related wiring. |

| Starter Motor | Engine won't crank | Check battery, solenoid, and starter motor. Inspect all related wiring. |

| Lights | Lights won't turn on | Test bulbs, fuses, switches, wiring, and ground connections. |

| Battery | Poor performance (low charge, corrosion) | Inspect battery voltage, clean terminals, charge as needed. |

Remember: If uncertain about any step, consult a qualified mechanic. Improper repairs can damage your tractor and may present significant safety risks. Safety must be your top priority.

Addressing Inconsistent Information in Wiring Diagrams

The most significant challenge lies in dealing with inconsistencies across various wiring diagrams. Model year variations and diverse sources account for these discrepancies. The solution: meticulous comparison, verification, and the use of a multimeter to confirm the actual wiring and current flow in your tractor. This process allows building a reliable version of the correct diagram through hands-on testing.

Key Takeaways:

- Accurate tractor identification is vital.

- Cross-reference wiring diagrams from multiple trusted sources.

- Follow a systematic troubleshooting approach.

- Always prioritize safety when working with electrical systems.

This guide provides a framework for successfully tackling your Ford 9N tractor's electrical issues. Remember to always consult multiple sources and proceed cautiously.